The tea plant’s inner make-up is only part of the story when it comes to the wonderful cup characteristics millions have come to love. In part 2 of the Science Behind Tea, we explore the science behind man’s manipulation of the tea leaf through the five main processing steps performed at origin: plucking, withering, rolling, oxidizing, and firing.

Even the best practices for growing and cultivating tea, to produce a delightful cuppa, can be ruined in the processing steps before it ever leaves origin. Understanding the science behind each step, requires decades of training. Those that are skilled enough to fulfill this life journey, are the true Tea Masters in our industry.

The first step, plucking, is the act of harvesting the fresh new growth (or flush). The plucking standard is determined by both the condition of the plant and the type of tea being produced. This can range from just the unfurled leaf bud to one-to-four leaves. However, for common teas, two leaves and a bud is the typical standard. Polyphenol concentration declines as the leaf ages. The older the leaf the less potential health benefits. Younger leaves contain more caffeine than older leaves. A fine plucking of the bud and the first leaf ensures higher caffeine levels. Increased temperature in the collection basket accelerates the degradation and lowers the overall quality of the leaf. Any breaking of the leaf during transportation encourages oxidation. Time is critical in the plucking stage since nothing can be done until the tea reaches the factory.

Once the tea has arrived at the factory, workers can start the second step, controlling the withering; though, withering essentially starts once the tea has been plucked. Withering is the process of reducing the moisture content of the leaf, to make it more pliable and to breakdown large complex molecules into simpler molecules. Physical withering reduces the moisture content by about 50% and concentrates the cellular compounds left behind. Additionally, the leaf becomes flaccid and more pliable for the following production steps. Chemical withering changes the chemistry in the leaf that contributes significantly to the teas color, aroma and flavor. Controlling this step is more art than science. Leave too much moisture in the leaf, the tea becomes moldy. Wither too long and the oxidation could be inhibited due to enzymes not being able to bond with polyphenols. Depending on the type of tea to be made, the weather, and machinery, this process can take from 1 hour to 2 days.

Once the tea has reached the right moisture level, it is transported to the rolling room; often referred to as the nerve center of the factory. The goal of rolling is to break open the cell walls within the leaf and dismantle the cellular organelles within the leaf tissue. During this process two essential compounds are released: polyphenol oxidase from the cytoplasm and polyphenols from the cell vacuoles. Rolling is also responsible for shaping the leaf. Whether it be flattened, curled, semi-balled, twisted, etc. the leaf shape has been perfected over centuries to preserve the essential oils within the leaf. These essential oils contain the volatile components that make up most of the aromatics of the tea and part of the tea’s taste characteristics.

Oxidation is a natural chemical process that turns the green leaf into shades of brown and black. This is similar to the browning of apple slices or falling leaves in fall. During oxidation, color, flavor and aroma are produced which are important to oxidized teas like black tea. Technically, oxidation started the moment cell disruption occurred; however, during this processing step, oxidization is controlled to produce specific types of tea. Polyphenol oxidase enzyme, which was released during rolling, catalyzes the oxidation process with the chemicals in the tea and oxygen in the air. With the help of this enzyme, polyphenols quickly oxidize into a compound that further reacts with the amino acids in the leaf, creating melanin, which is brown in color. This enzymatic browning oxidation is critical to the development of aromas and flavor compounds found in partially oxidized oolongs and fully oxidized black teas.

During the final processing step of firing two important objectives are obtained. The first is to stop the oxidation process and second, to remove most of the remaining moisture from the leaf to make the product shelf stable. By applying heat, the enzyme which is responsible for oxidation is denatured and rendered permanently inactive. Heat must be applied quickly to discourage rapid oxidation, but not too fast as to burn the leaves. To make it shelf stable for transport via container ship, it is essential that moisture be reduced to a level below 4%, as additional moisture is gained during transit. A level below 8% is required to make the tea shelf stable enough to be enjoyed for years. On average, 100 pounds of fresh tea yields about 22 pounds of finished tea.

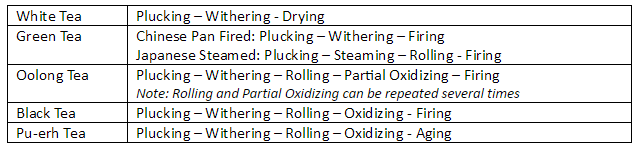

It is important to note that not all teas go through each of the above steps. The type of tea determines the processing methods used. Below is a quick reference chart of the five basic tea types and the typical processing steps that occur.

As you can see, the simple tea you have come to enjoy is not so simple. A lot of skill and understanding of the science behind tea is critical to ensure consistent tea quality, crop after crop. Next time you brew up a pot of your favorite tea from Art of Tea, remember all that has impacted that cuppa you have come to enjoy.

Art of Tea is an award winning purveyor of specialty and organic teas, based in Los Angeles, CA.

If you found this article helpful, please share it with coworkers, colleagues, and fellow lovers of tea.